Experienced Dive Team Assists in Construction of New Quay Wall in Antwerp Port

Published on: 22/02/2024

Experienced Dive Team Assists in Construction of New Quay Wall in Antwerp Port

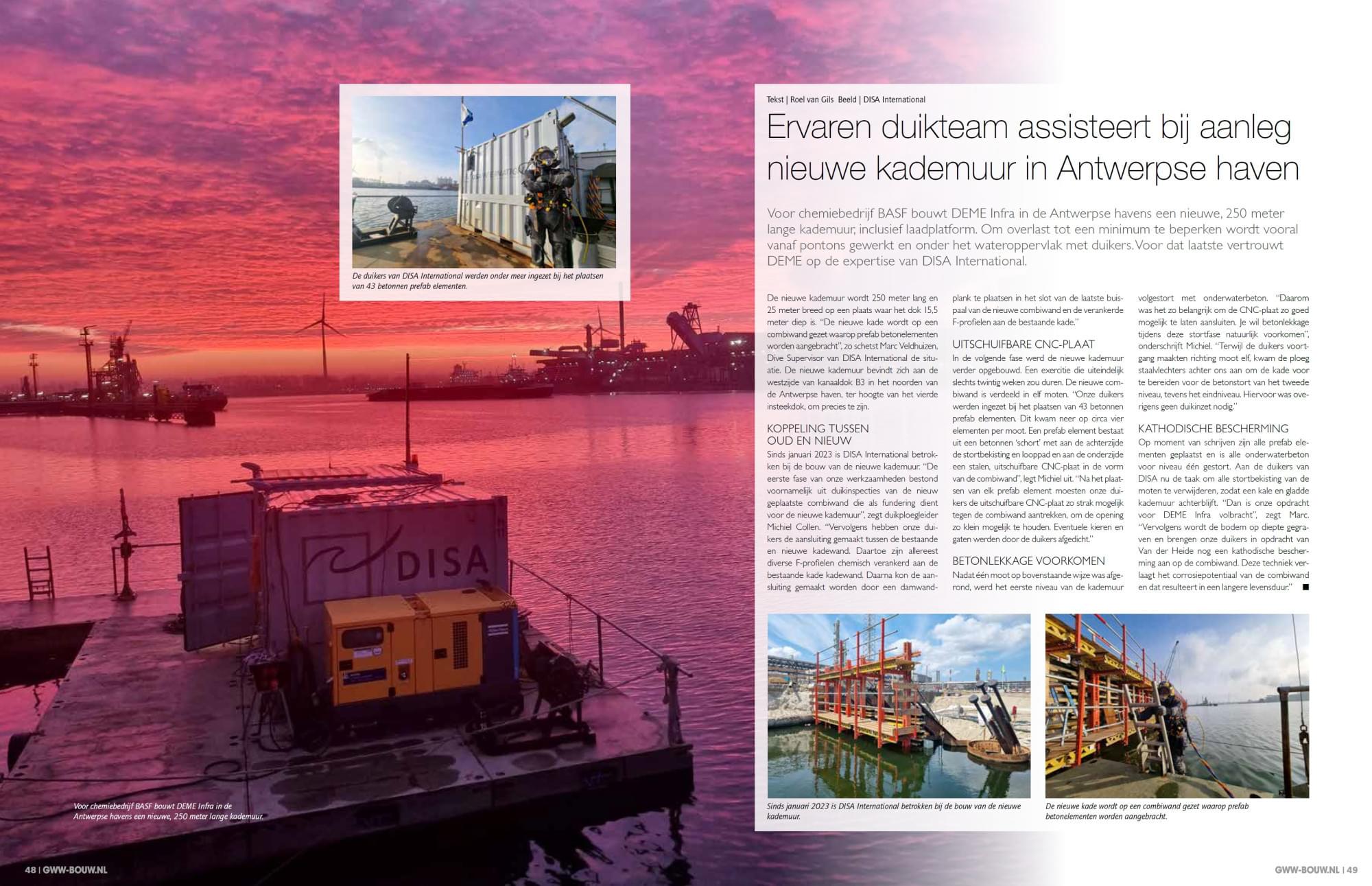

DEME Infra is constructing a new quay wall, including a loading platform, in the Antwerp ports, spanning 250 meters in length for the chemical company BASF. To minimize disruptions, the project is predominantly carried out from pontoons and underwater with the assistance of divers. For the underwater tasks, DEME relies on the expertise of DISA International. The new quay wall, measuring 250 meters in length and 25 meters in width, is being built in a location where the dock reaches a depth of 15.5 meters.

"The new quay will be placed on a combi-wall, onto which prefabricated concrete elements will be applied," explains Marc Veldhuizen, Dive Supervisor at DISA International, outlining the situation. The new quay wall is situated on the west side of canal dock B3 in the northern part of the Antwerp port, precisely at the fourth inlet dock.

Linking Old and New

Since January 2023, DISA International has been involved in the construction of the new quay wall. "The initial phase of our work mainly consisted of dive inspections of the newly placed combi-wall, serving as the foundation for the new quay wall," says dive team leader Michiel Collen. "Subsequently, our divers connected the existing and new quay walls. To achieve this, various F-profiles were first chemically anchored to the existing quay wall. Then, the connection was made by placing a sheet pile into the slot of the last tube pile of the new combi-wall and attaching it to the anchored F-profiles on the existing quay."

Extendable CNC Plate

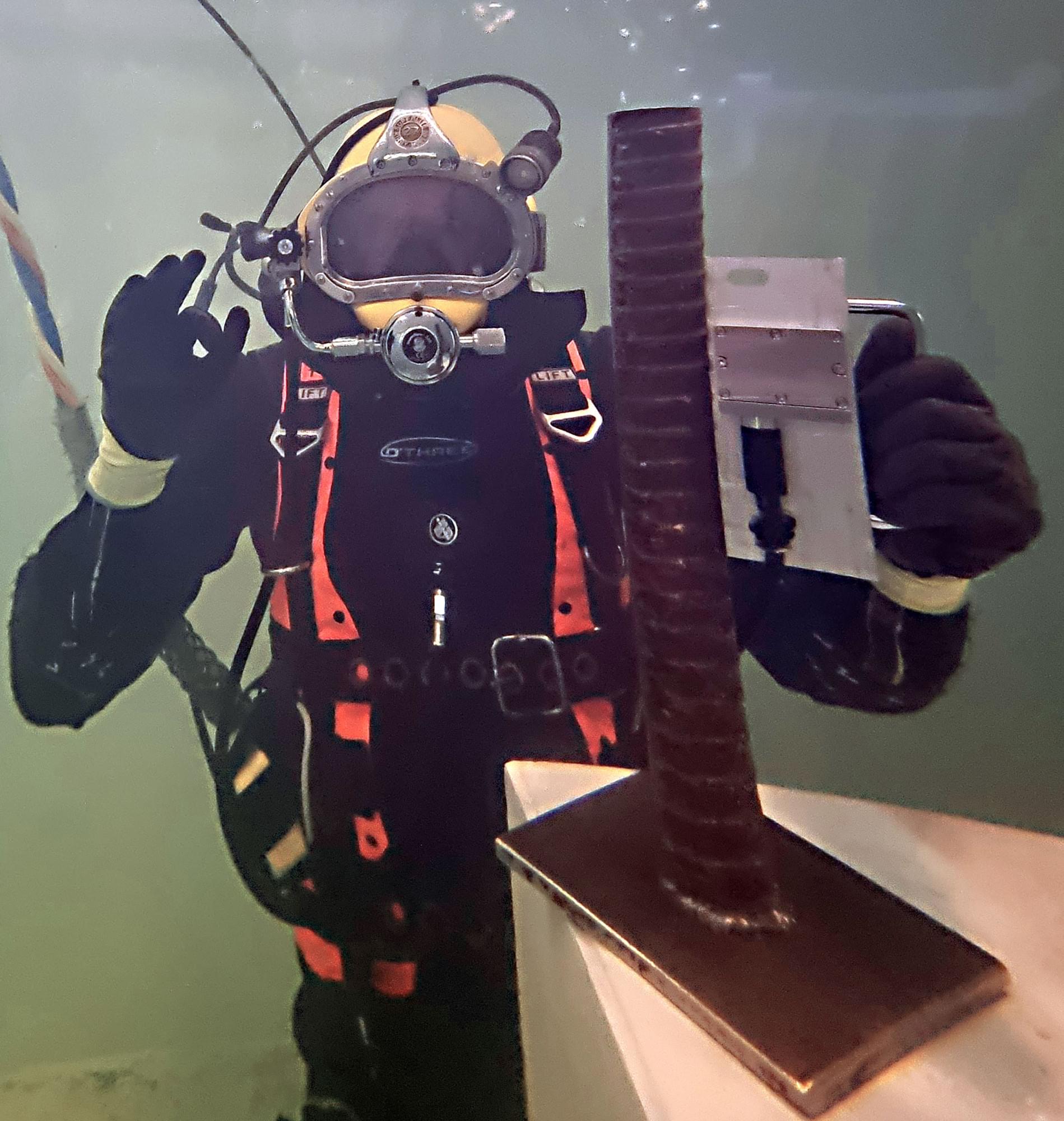

In the next phase, the construction of the new quay wall continued, a process that would ultimately take only twenty weeks. The new combi-wall is divided into eleven sections. "Our divers were involved in placing 43 concrete prefabricated elements, approximately four elements per section. A prefabricated element consists of a concrete 'apron' with the formwork and walkway at the back and an extendable steel CNC plate at the bottom, shaped like the combi-wall," explains Michiel. "After placing each prefabricated element, our divers had to pull the extendable CNC plate tightly against the combi-wall to minimize the opening. Any gaps and holes were sealed by the divers."

Preventing Concrete Leakage

Once one section was completed in the above manner, the first level of the quay wall was filled with underwater concrete. "That's why it was crucial to ensure a tight fit with the CNC plate. Preventing concrete leakage during this pouring phase is essential," emphasizes Michiel. "While the divers progressed towards section eleven, the team of steel fixers followed to prepare the quay for the concrete pouring of the second level, also the final level. No diving intervention was required for this."

Cathodic Protection

As of the current writing, all prefabricated elements are in place, and underwater concrete for level one has been poured. The next task for DISA divers is to remove all formwork from the sections, leaving a bare and smooth quay wall. "Once that is done, our mission for DEME Infra will be completed," says Marc. "Subsequently, the seabed will be excavated to depth, and our divers, on behalf of Van der Heide, will apply cathodic protection to the combi-wall. This technique reduces the corrosion potential of the combi-wall, resulting in an extended lifespan."